SCHNAITHMANN is a system integrator and automation specialist. With 245 employees, the medium-sized company supplies product-specific individual systems for automobile manufacturers and suppliers, tool manufacturers, consumer goods producers and electronics manufacturers. For the worldwide support of its customers and service partners, SCHNAITHMANN has been using the remote support platform oculavis SHARE since February 2020.

Germany’s small and medium-sized companies (SMEs), also known as the “Mittelstand”, are drivers of economy and innovation, export their products on a global scale and are the warrantor of the quality feature “Made in Germany”. The special machine manufacturer SCHNAITHMANN represents all these attributes. However, despite the highest level of engineering skills, problems on the end customer side start with every sale of a system. Unplanned downtimes, repairs or maintenance require permanent availability in customer service. For a medium-sized company with limited financial and personnel capacities, new collaboration solutions are required to meet this demand.

The individuality and precise adaptation to customer requirements make every SCHNAITHMANN system unique. The managers and employees involved in the project are the experts and build up a specific knowledge base for each system. Consequently, they are also the ones who support the customer in the field in case of a malfunction. In addition, the company has service cooperations with experienced partners worldwide for its internationally operating customers, who rely on the existing know-how of the German colleagues. Experience has shown that often little things cause problems for which the project participants used to travel around the world. The resulting inefficiency ties up valuable resources, which are required to work on really urgent service cases promptly. In autumn 2019, SCHNAITHMANN decided to make a fundamental change in the way processes and communication in customer service are done by implementing a remote support solution.

The range of remote support solution providers is large. Getting an overview, not to mention in finding the suitable software for the own organization and the intended use case, requires a structured approach. The selection process at SCHNAITHMANN took place in three steps:

SCHNAITHMANN critically scrutinized all customer service processes to determine the application areas. The analysis resulted in three scenarios, which the management expected to deliver significant time and cost savings as well as a reduction in the workload for employees within short time. In the future, preliminary acceptance tests of systems at the SCHNAITHMANN factory, final commissioning at the customer’s site as well as fault diagnosis and troubleshooting should be carried out remotely. The company also aims at improving the support for its global service partners.

.

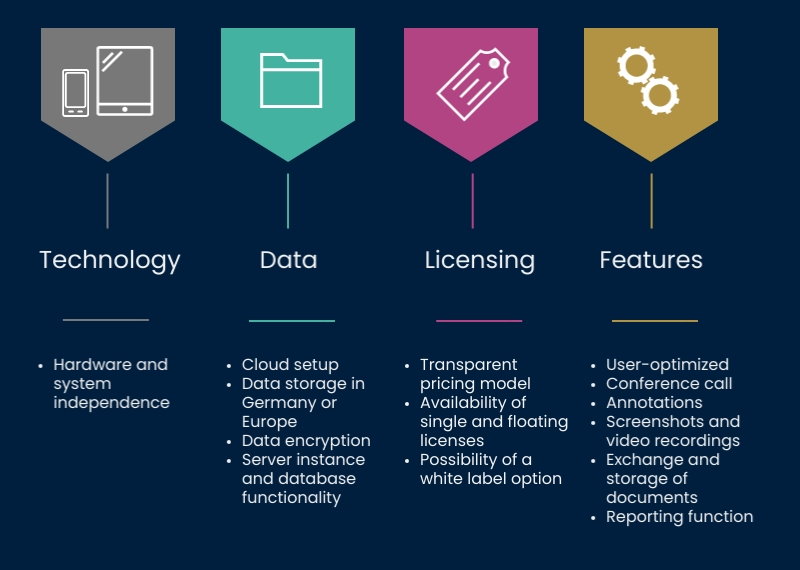

In the second step, a list of requirements was drawn up, which a remote service solution should include to fulfil future tasks (see the following figure).

From a technical point of view, the software should be useable on different devices. Availability on iOS and Android mobile phones and tablets was particularly important to SCHNAITMANN, as both are an integral part of technical customer service and therefore no additional hardware investment would be necessary.

SCHNAITHMANN decided from the very first beginning that the software provider should take over the cloud hosting. As a requirement, the company stated that the workspace should be set up on a German or European cloud in compliance with the General Data Protection Regulation (GDPR). In addition, a dedicated server instance and databases must exist so that the data is physically separated from other companies. Another mandatory criterion was the encryption of data and video connections.

Finally, the company defined several features that are indispensable for the usage in following live operations. The industrial video call should work with several participants. Annotations should support the communication by using visual elements in addition to voice instructions, which can be faded into the visional field of the service technician to improve the expert guidance. Screenshots and video recordings should document the service case in order to store valuable knowledge and, if required, make it available as a service report for the end customer.

At the end of the selection process, SCHNAITHMANN decided to use oculavis and its remote service platform oculavis SHARE in February 2020. One of the main reasons stated by Volker Sieber, head of development at SCHNAITHMANN and project manager, is the user-optimized and intuitive operation of the solution. Long familiarization phases and additional training of all participants are not necessary. Thanks to the cloud setup on Microsoft Azure Europe in Amsterdam with dedicated server instances and databases, the software solution was immediately ready for use and could therefore be easily integrated into the existing IT landscape.

The service processes are covered in so called cases of oculavis SHARE. Preliminary acceptance tests and final commissioning can be planned in the best possible way. External users such as customers or service partners receive personalized access and authorizations for HD video calls or to view product documentation through the user management in oculavis SHARE. The process steps to be carried out can be created in advance and required documents can be stored in the service case. Open points can be reviewed and finally clarified through the case history.

SCHNAITHMANN and its customers have maximum security in the live video call, because the data and video connection is encrypted. Screenshots and video recordings document the work carried out and are automatically assigned to the service case during the live session, which saves time-consuming rework. A case report contains all information such as metadata, screenshots or comments and can be provided to the customer as a final technical documentation of the service work.

Remote Expert Support enables the mechanical engineering company to carry out acceptance test and commissioning of systems as well as troubleshooting remotely. Employees are relieved and analog and paper-based activities are replaced by digital service processes. This leads to increased efficiency in the support of customers and service partners, reduces travel times and costs and empowers SCHNAITHMANN to create an innovative service experience.

SCHNAITHMANN would like to cover even more applications remotely in the future. For example, the use of oculavis SHARE in technical sales by guiding customers in virtual tours through its technical center is planned as well. Technical details of a system expansion can be clarified remotely without physically visiting the customer. Spare parts can be checked and reordered in agreement with the customer during scheduled maintenance. Furthermore, first approaches exist to monetize the new service offer by making oculavis SHARE completely available as a white label application for SCHNAITHMANN.

As one of the leading system suppliers in automation technology, SCHNAITHMANN has been serving customers since 1985. With a wide range of services, the company provides quality solutions in assembly, material flow and handling technology. Customers receive all services from one competent source, from planning to components to complete systems.