Blending electrification trends and sustainability goals with digital solutions

The market for electric vehicles has grown significantly. As a 360° system integrator, elexon uses

The market for electric vehicles has grown significantly. As a 360° system integrator, elexon uses

TÜV SÜD Energietechnik digitizes its processes with the smart service platform from oculavis. New standards

Holcim, a leader in the construction industry with 63,000 employees worldwide, has recently integrated the

In a remarkable achievement that underscores the transformative power of digital innovation in customer service

Networking, automation, and data-driven services provide valuable insights into production processes in mechanical and plant

As a successful provider of visual assistance and augmented reality solutions, we can state one

The market for electric vehicles has grown significantly. As a 360° system integrator, elexon uses

TÜV SÜD Energietechnik digitizes its processes with the smart service platform from oculavis. New standards

Holcim, a leader in the construction industry with 63,000 employees worldwide, has recently integrated the

In a remarkable achievement that underscores the transformative power of digital innovation in customer service

Networking, automation, and data-driven services provide valuable insights into production processes in mechanical and plant

As a successful provider of visual assistance and augmented reality solutions, we can state one

KraussMaffei and oculavis introduce a service platform for maintenance and service in the VDMA magazine

Open exchange sessions between the participants of the ARxelerator program currently take place every Friday.

In September 2021, oculavis GmbH and ISAP AG celebrate their second partnership anniversary.

As the leading full-service provider for the cement industry, the cement technologies business unit of

SCHNAITHMANN is a system integrator and automation specialist. With 245 employees

The current situation has changed a lot: We are shopping with mouth-and-nose masks, have reduced

The GEBHARDT Intralogistics Group has successfully established a digital business model in after sales service

In the course of the Corona Pandemic, a large number of industrial companies have completely

Many customers and interested parties from the mechanical and plant engineering industry tell me again

PRODUCT

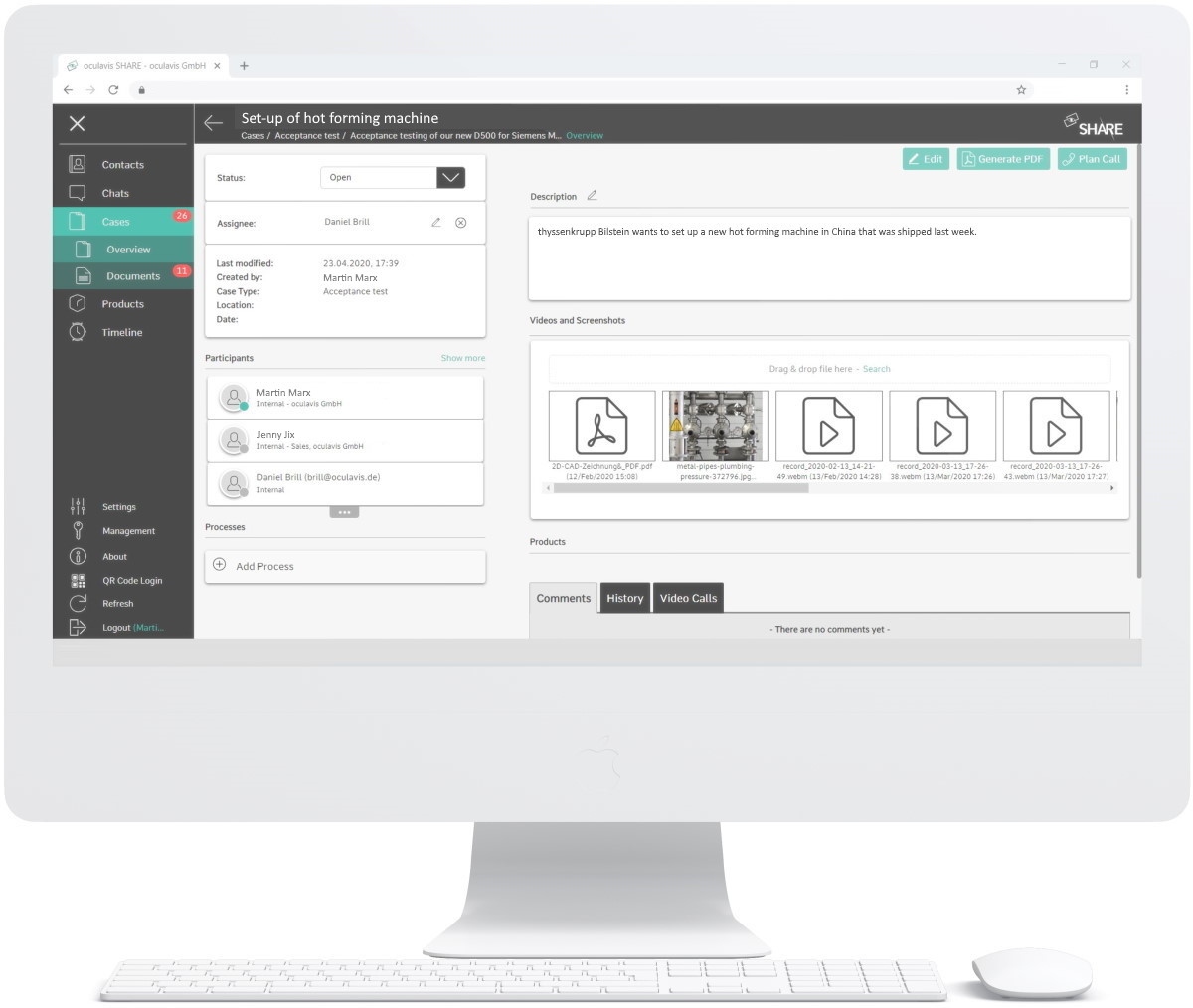

Smart Service & Connected Worker Platform

Ticketing & Work Order Management

Standard Operating Procedures

Visual Assistance

Service Access Point

Management & Configuration

Integration

White Label Solutions

Secure & Scalable in the Cloud

Pricing & Licenses

SOLUTIONS

Machinery & Equipment Manufacturing

Manufacturing Industry & Automotive

Energy & Utilities

Pharma & Life Sciences

Construction Machinery & Off Highway

Certification & Industrial Services

Customer Service

Technical Field Service

Acceptances, Inspections & Audits

Technical Sales & Consulting

RESOURCES