SMART SERVICE & CONNECTED WORKER PLATTFORM

As the leading platform, oculavis SHARE redesigns processes between humans and machines.

SMART SERVICE PLATFORM FOR MECHANICAL ENGINEERING

oculavis SHARE is a holistic platform for the design, execution, and management of smart service processes for your installed base.

It serves as a central point of contact for end users to interact with the manufacturer, access self-service offers and receive personalized service.

In technical field service, oculavis SHARE acts as a service app for optimal support with ticket management, digital work instructions, visual assistance, and access to machine documentation.

As an end-to-end service platform, oculavis SHARE simplifies and structures communication with global service partners to document, analyze and solve service cases.

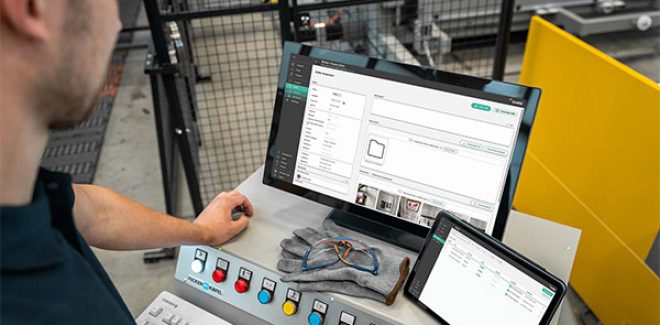

CONNECTED WORKER PLATTFORM FOR MANUFACTURING COMPANIES

oculavis SHARE is designed to improve the communication, collaboration, and efficiency of shop floor employees.

With connected worker solutions, you can switch from paper-based to digital and interactive work instructions, e.g. for set-up processes or for training new employees. Create tickets for maintenance and inspections directly at the machine.

Link these with step-by-step guides, reports, and logs, and provide the users with valuable knowledge about the machinery. Or carry out future audits remotely, regardless of location and time.

KEY FEATURES OF THE OCULAVIS SMART SERVICE & CONNECTED WORKER PLATFORM

Document, Track and Manage Tasks

Creating tickets, reports, suggestions for improvement or notifications, assigning responsibilities and documenting work progress is possible with the oculavis’ ticketing & work management.

Digital Work Instructions

Digital workflows provide knowledge in a structured form for recurring and standardized activities on machinery and equipment. They are also excellent for training and qualification.

Live Communication and

-Collaboration

oculavis SHARE is designed for technical collaboration. Enriched with AR features and integrated chat, experts, technicians, machine operators or auditors communicate and collaborate remotely at the highest quality.

Technical Knowledge on Demand

Using oculavis, specialist personnel have access to machine documentation, maintenance documents, digital step-by-step guides, responsible experts, or the ticket history of a machine.

Seamless in Systems for End-to-End Process

oculavis SHARE integrates seamlessly into third-party systems, either as an individual integration with any system or as a provided standard integration for e.g. Salesforce or Microsoft Outlook.

Your Solutions in your Corperate Design

You become the provider of your smart service and connected worker solutions with the white label options of oculavis SHARE.

Document, Track and Manage Tasks

Creating tickets, reports, suggestions for improvement or notifications, assigning responsibilities and documenting work progress is possible with the oculavis’ ticketing & work management.

Technical Knowledge on Demand

Using oculavis, specialist personnel have access to machine documentation, maintenance documents, digital step-by-step guides, responsible experts, or the ticket history of a machine.

Seamless in Systems for End-to-End Processes

oculavis SHARE integrates seamlessly into third-party systems, either as an individual integration with any system or as a provided standard integration for e.g. Salesforce or Microsoft Outlook.

Your Solutions in your Corporate Design

You become the provider of your smart service and connected worker solutions with the white label options of oculavis SHARE.

Live Communikation and-Collaboration

oculavis SHARE is designed for technical collaboration. Enriched with AR features and integrated chat, experts, technicians, machine operators or auditors communicate and collaborate remotely at the highest quality.

Digital Work Instructions

Digital workflows provide knowledge in a structured form for recurring and standardized activities on machinery and equipment. They are also excellent for training and qualification.

Document, Track and Manage Tasks

Creating tickets, reports, suggestions for improvement or notifications, assigning responsibilities and documenting work progress is possible with the oculavis’ ticketing & work management.

Digital Work Instructions

Digital workflows provide knowledge in a structured form for recurring and standardized activities on machinery and equipment. They are also excellent for training and qualification.

Live Communication and-Collaboration

oculavis SHARE is designed for technical collaboration. Enriched with AR features and integrated chat, experts, technicians, machine operators or auditors communicate and collaborate remotely at the highest quality.

Technical Knowledge on Demand

Using oculavis, specialist personnel have access to machine documentation, maintenance documents, digital step-by-step guides, responsible experts, or the ticket history of a machine.

Seamless in Systems for End-to-End Processes

oculavis SHARE integrates seamlessly into third-party systems, either as an individual integration with any system or as a provided standard integration for e.g. Salesforce or Microsoft Outlook.

Your Solutions in your Corporate Design

You become the provider of your smart service and connected worker solutions with the white label options of oculavis SHARE.

SMART SERVICE IN MECHANICAL ENGINEERING

The right approach for sustainable success.

WHITEPAPER

- How can you identify new use cases in customer service systematically?

- How do you unlock new revenue streams with smart service platforms?

- How do you prepare a technical-organizational implementation?

- How do you structure a proof of concept (PoC) project?

WHITEPAPER

- How can you identify new use cases in customer service systematically?

- How do you unlock new revenue streams with smart service platforms?

- How do you prepare a technical-organizational implementation?

- How do you structure a proof of concept (PoC) project?

“The demographic trend is evident. The shortage of skilled

workers is a huge challenge. The visual assistance

solution from oculavis is our answer to taking customer

service to the next level, using experts more efficiently,

and increasing the availability of our globally installed

machine base..”

Andreas Baumann

Head of Business Development – Customer Service Construction Machines, Liebherr-Werk Nenzing GmbH

“Thanks to our remote service, we are able to let our customers see through the eyes of our experts, so we are close to them – even if they are far away.“

Jennifer Richardt

Product Manager Digital Services, thyssenkrupp Industrial Solutions AG, Business Unit Polysius

“At Hüller Hille, tradition does not mean sticking to old principles, but constantly breaking new ground into the future.”

Pierre Stadler

Group Director Service,

Hüller Hille GmbH

MORE THAN 200 COMPANIES ALREADY RELY ON OUR PLATFORM

When will you join us?

READY FOR AN EXCHANGE?

oculavis SHARE offers you smart service and connected worker solutions that fit seamlessly into your processes. The possibilities are endless. Explore new potential for your organization together with our experts!

We look forward to talking to you!

DISCOVER INNOVATIVE PROCESS

The Industrial Metaverse. Definition, applications and potentials in mechanical engineering & the industry

The Industrial Metaverse. Definition, applications and potentials in mechanical engineering & the industry

Workflows: Just-in-time knowledge for the next generation

Innovative service experience with AR video support in the machine tool industry