Blending electrification trends and sustainability goals with digital solutions

The market for electric vehicles has grown significantly. As a 360° system integrator, elexon uses

The market for electric vehicles has grown significantly. As a 360° system integrator, elexon uses

TÜV SÜD Energietechnik digitizes its processes with the smart service platform from oculavis. New standards

Holcim, a leader in the construction industry with 63,000 employees worldwide, has recently integrated the

In a remarkable achievement that underscores the transformative power of digital innovation in customer service

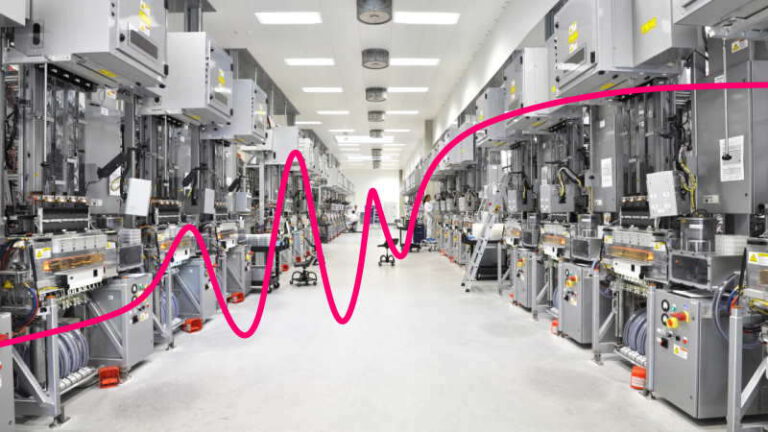

Networking, automation, and data-driven services provide valuable insights into production processes in mechanical and plant

As a successful provider of visual assistance and augmented reality solutions, we can state one

The market for electric vehicles has grown significantly. As a 360° system integrator, elexon uses

TÜV SÜD Energietechnik digitizes its processes with the smart service platform from oculavis. New standards

Holcim, a leader in the construction industry with 63,000 employees worldwide, has recently integrated the

In a remarkable achievement that underscores the transformative power of digital innovation in customer service

Networking, automation, and data-driven services provide valuable insights into production processes in mechanical and plant

As a successful provider of visual assistance and augmented reality solutions, we can state one

KraussMaffei and oculavis introduce a service platform for maintenance and service in the VDMA magazine

Open exchange sessions between the participants of the ARxelerator program currently take place every Friday.

As the leading full-service provider for the cement industry, the cement technologies business unit of

SCHNAITHMANN is a system integrator and automation specialist. With 245 employees

The current situation has changed a lot: We are shopping with mouth-and-nose masks, have reduced

Tier 1 automotive supplier thyssenkrupp Bilstein relies on oculavis SHARE to connect its production sites

The GEBHARDT Intralogistics Group has successfully established a digital business model in after sales service

In the course of the Corona Pandemic, a large number of industrial companies have completely

Many customers and interested parties from the mechanical and plant engineering industry tell me again

PRODUCT

Smart Service & Connected Worker Platform

Ticketing & Work Order Management

Standard Operating Procedures

Visual Assistance

Service Access Point

Management & Configuration

Integration

White Label Solutions

Secure & Scalable in the Cloud

Pricing & Licenses

SOLUTIONS

Machinery & Equipment Manufacturing

Manufacturing Industry & Automotive

Energy & Utilities

Pharma & Life Sciences

Construction Machinery & Off Highway

Certification & Industrial Services

Customer Service

Technical Field Service

Acceptances, Inspections & Audits

Technical Sales & Consulting

RESOURCES