The Industrial Metaverse. Definition, applications and potentials in mechanical engineering & the industry

It seems that nowadays all leading companies of different industries are rushing into the metaverse:

It seems that nowadays all leading companies of different industries are rushing into the metaverse:

Together with the Chair of Digital Communication Systems at Ruhr University Bochum, SMS Digital GmbH,

Artificial intelligence (AI) is one of the hype topics that has been driving machinery and

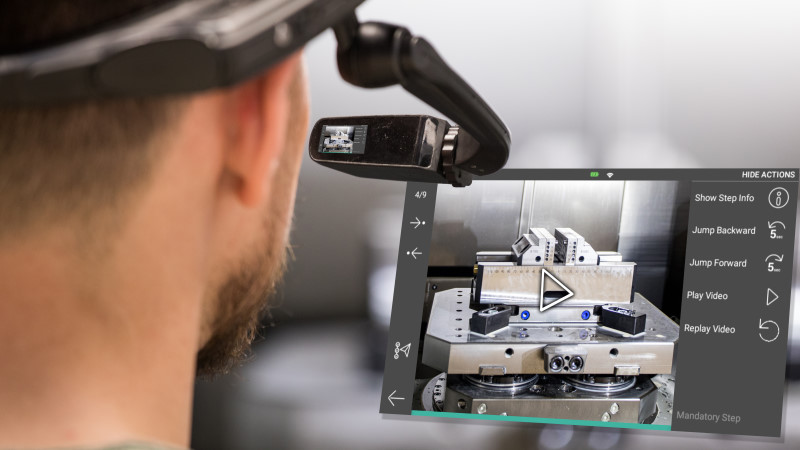

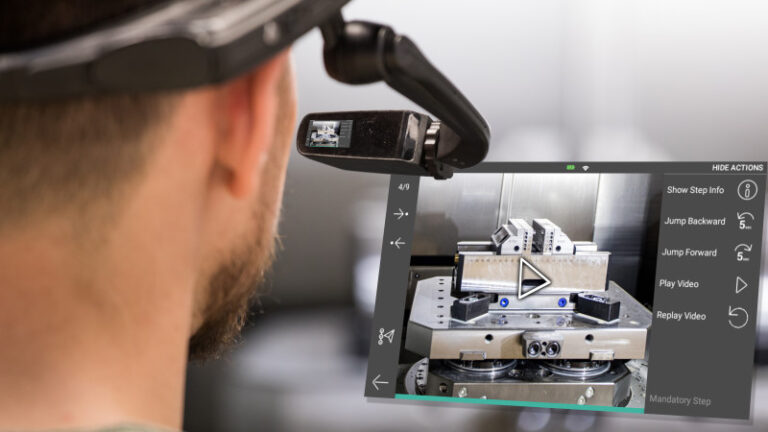

The multiple award-winning Augmented Reality based remote support platform oculavis SHARE is extended by a

On January 15th 2020, Microsoft Edge launched a new, Chromium-based browser, with the purpose to

The market for augmented reality headsets, also known as smart glasses has gone through a

It seems that nowadays all leading companies of different industries are rushing into the metaverse:

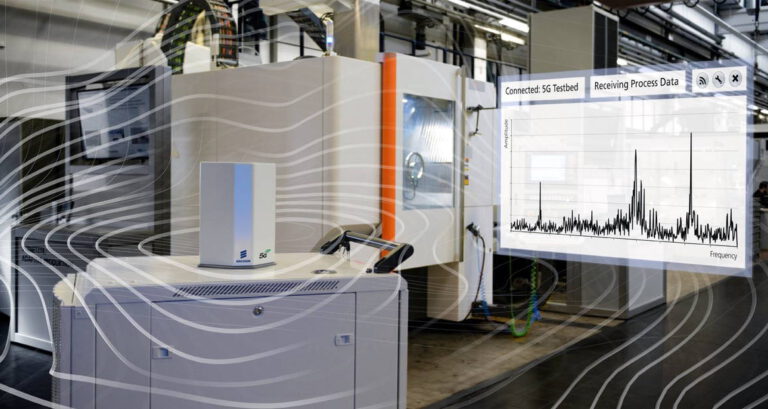

Together with the Chair of Digital Communication Systems at Ruhr University Bochum, SMS Digital GmbH,

Artificial intelligence (AI) is one of the hype topics that has been driving machinery and

The multiple award-winning Augmented Reality based remote support platform oculavis SHARE is extended by a

On January 15th 2020, Microsoft Edge launched a new, Chromium-based browser, with the purpose to

The market for augmented reality headsets, also known as smart glasses has gone through a

Together with seven partners from research and industry, oculavis GmbH is developing Augmented Reality (AR)

PRODUCT

Smart Service & Connected Worker Platform

Ticketing & Work Order Management

Standard Operating Procedures

Visual Assistance

Service Access Point

Management & Configuration

Integration

White Label Solutions

Secure & Scalable in the Cloud

Pricing & Licenses

SOLUTIONS

Machinery & Equipment Manufacturing

Manufacturing Industry & Automotive

Energy & Utilities

Pharma & Life Sciences

Construction Machinery & Off Highway

Certification & Industrial Services

Customer Service

Technical Field Service

Acceptances, Inspections & Audits

Technical Sales & Consulting

RESOURCES