Remote assistance, remote support, and visual assistance

Explore the differences between remote assistance, remote support, and visual assistance to enhance the effectiveness

Explore the differences between remote assistance, remote support, and visual assistance to enhance the effectiveness

Discover how the Industrial Metaverse is already being applied in manufacturing today and the concrete

The main innovation of the latest version 9.0 of the remote process platform oculavis SHARE

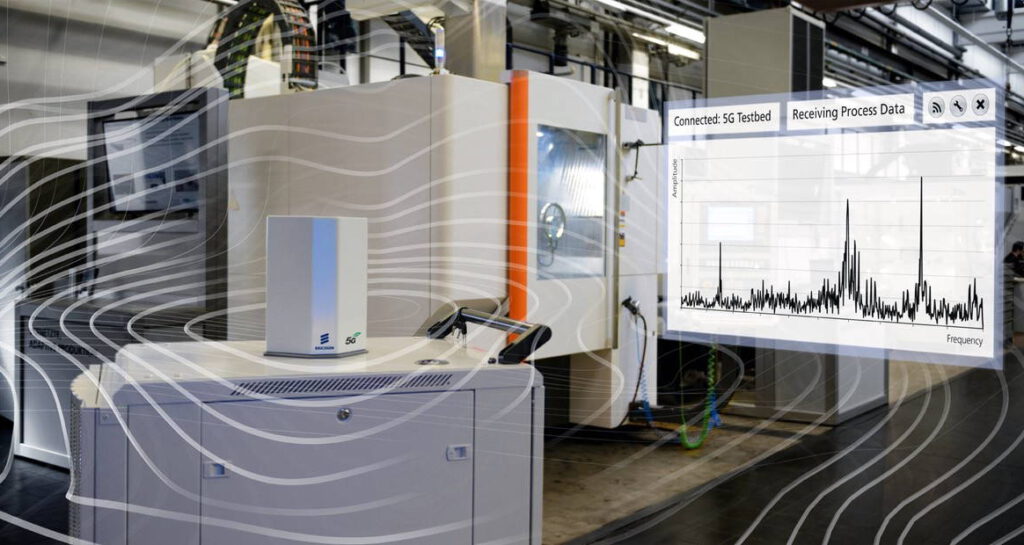

Together with the Chair of Digital Communication Systems at Ruhr University Bochum, SMS Digital GmbH,

How AI and Augmented Reality (AR) enhance manufacturing through Predictive Maintenance and Analytics

The multiple award-winning Augmented Reality based remote support platform oculavis SHARE is extended by a

Explore the differences between remote assistance, remote support, and visual assistance to enhance the effectiveness

Discover how the Industrial Metaverse is already being applied in manufacturing today and the concrete

The main innovation of the latest version 9.0 of the remote process platform oculavis SHARE

Together with the Chair of Digital Communication Systems at Ruhr University Bochum, SMS Digital GmbH,

How AI and Augmented Reality (AR) enhance manufacturing through Predictive Maintenance and Analytics

The multiple award-winning Augmented Reality based remote support platform oculavis SHARE is extended by a

On January 15th 2020, Microsoft Edge launched a new, Chromium-based browser, with the purpose to

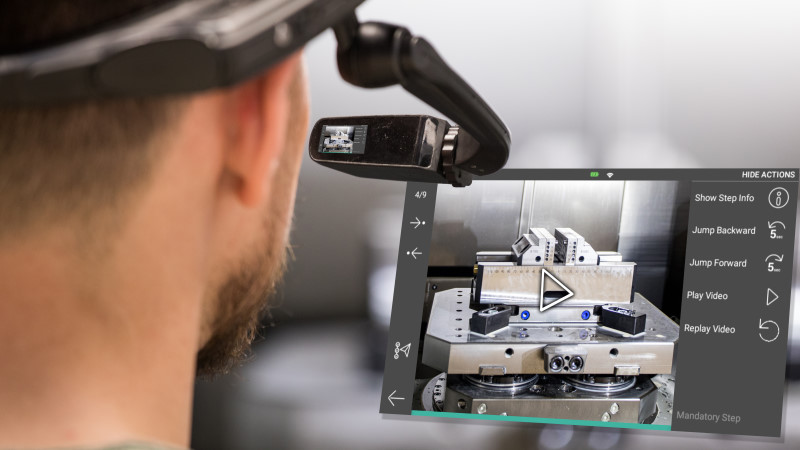

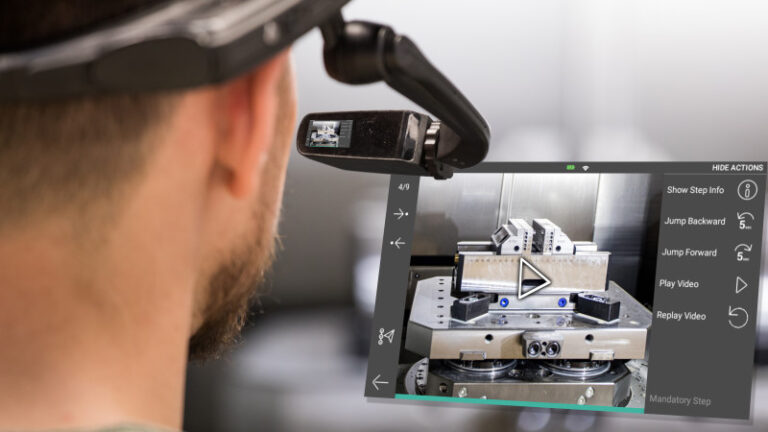

The market for augmented reality headsets, also known as smart glasses has gone through a

PRODUCT

Smart Service & Connected Worker Platform

Ticketing & Work Order Management

Standard Operating Procedures

Visual Assistance

Service Access Point

Management & Configuration

Integration

White Label Solutions

Secure & Scalable in the Cloud

Pricing & Licenses

SOLUTIONS

Machinery & Equipment Manufacturing

Manufacturing Industry & Automotive

Energy & Utilities

Pharma & Life Sciences

Construction Machinery & Off Highway

Certification & Industrial Services

Customer Service

Technical Field Service

Acceptances, Inspections & Audits

Technical Sales & Consulting

RESOURCES